Publication time:2022-05-27 Page views:843

As an important main power distribution line, the busway is now being used more and more widely.CG BUSWAY:“Only by purchasing high-quality busway can we effectively ensure the safety of our lives and property.”Countless examples of serious accidents have occurred due to the use of inferior busway.

For example, a domestic bread supplier once selected a certain brand of busway at a low price due to the need for upgrading factory equipment, but because the busway products of this brand had issues of cutting corners and reducing materials, a serious safety hazard was hidden. Some time later, more than 30 production line machines were damaged due to short circuits in the electrical circuits, ultimately leading to a major safety incident where the entire factory was burned down.

A dam may collapse from an ant hole.No one wants to experience a major safety incident. What we need to do is to prevent it from happening. CG BUSWAY reminds you: Choose high-quality busway to truly ensure the safety of your life and property.

Next, CG BUSWAY will show you the chaos in the busway industry.

1. The chaos of the CG BUSWAY astounds you

The surface of inferior CG BUSWAY looks great, but in reality, the inside is appalling. All of this is a deceptive tactic played by inferior manufacturers to save costs and deceive consumers, but it is indeed a potential safety hazard for consumers.

The CG BUSWAY market is mixed, and some manufacturers often attract customers with the "lowest price." CG BUSWAY can easily list some common problems when purchasing CG BUSWAY:

1. Copper at both ends, aluminum in the middle

The conductivity of aluminum is worse than copper, and the price is cheaper than copper. Some manufacturers deceive customers by using aluminum bars in the middle of CG BUSWAY instead of copper bars to save costs, leading to potential safety hazards in customer electricity usage.

2. Poor insulation material quality

Some manufacturers use inferior insulation materials to wrap the conductors of CG BUSWAY, such as heat-shrink tubing supported by inferior materials or low-grade polyester tubing, resulting in insufficient insulation and poor heat resistance, which can easily cause the CG BUSWAY to heat up, short circuit, and thus affect the overall service life of the CG BUSWAY.

3. Welding Soft Connections

When welding soft connections, it is more prone to oxidation and heating, which in turn affects the conductivity and lifespan of the busway.

4. Poor Welding Process

A poor welding process for the busway can lead to fractures at the welded joints, affecting the mechanical strength and lifespan of the busway.

5. Substandard Tin Plating due to Cutting Corners

Tin plating is used to enhance the conductivity and oxidation resistance of the busway conductor. However, a too thin tin plating layer can easily lead to oxidation corrosion on the surface of the busway, thereby affecting its overall lifespan.

6. Substituting Brass for Copper

Some manufacturers may use T3 brass instead of T1 or T2 copper to save on production costs. However, T3 brass typically has lower purity and does not meet the conductivity requirements of copper. This can result in poor electrical performance of the busway, increased power consumption, and even short circuits due to excessive temperature rise.

7. Thin as Cicada Wings

Some manufacturers use aluminum shells as thin as cicada wings for their busway housings, making the busway housing prone to deformation, low mechanical strength, and easy damage.

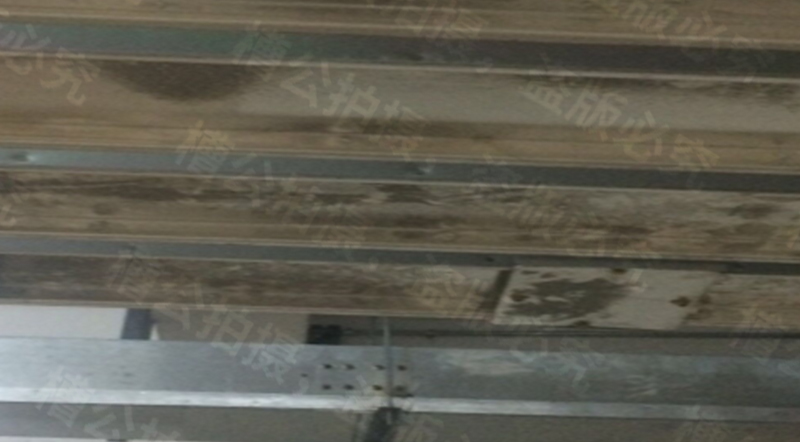

8. Poor Connection Structure

The connector's poor connection structure can lead to loose connections, fractures, moisture ingress at the busway joints, and in severe cases, short circuits causing the busway to burn out. In the image below, the connector corrodes due to moisture, leading to decreased conductivity and higher power consumption.

9. Side Panels without Heat Dissipation Fins

To save costs, some manufacturers produce busways with side panels lacking heat dissipation fins, which hinders heat dissipation and reduces the busway's lifespan.

10. Halving the Neutral Wire through Shoddy Workmanship

For commercial busway systems, the neutral wire (N) should be of the same quality as the phase wire, typically 100%. However, some businesses cut corners by halving the neutral wire, deceiving consumers to save costs. Halving the neutral wire poses serious safety hazards. For instance, as shown in the image below, a mere 2 cm of shoddy workmanship led to a short circuit and the burning of the entire busway during operation.

Online

Service