Publication time:2022-12-13 Page views:562

The 2022 Qatar World Cup is in full swing, with the Lusail Stadium as one of the main venues attracting a lot of attention from football fans.

It is worth mentioning that the Luzhniki Stadium is the only World Cup main stadium among the eight competition venues built by a Chinese company for the first time as the main contractor. The construction contractor is China Railway Construction Corporation Limited.

The design inspiration of the Luzhniki Stadium comes from traditional Qatari lantern patterns and date palm bowls, with a style that is highly characteristic of the Middle East. The overall shape is bowl-like, the roof is saddle-shaped, and the outer curtain wall is a golden double-curved aluminum panel curtain wall, aptly dubbed by netizens as the“Golden Bowl”.

The Luzhniki Stadium is the most complex World Cup venue globally, with all its MEP systems controllable directly through terminals. Additionally, it features the world's largest span double-layer intersecting cable net roof structure. Crafted by Chinese artisans, this marvel of engineering and clever design boasts a total built area of 195,000 square meters. The steel structure assembly precision error stands within 3 millimeters, with spatial position errors of all nodes within 25 millimeters and cable force deviations not exceeding 10%. What a marvel of engineering and clever design!

Great engineering quality is often considered the foundation of a project, while ingenious design is seen as its soul. Chinese craftsmen have conquered the construction challenges brought by circular architecture, creating a series of world-class achievements with their strong planning capabilities.

The world's largest-span double-layer cable net roof single-structure building;

The world's largest-scale FIFA World Cup main stadium;

The world's most complex FIFA World Cup main stadium system;

The world's highest design standard FIFA World Cup main stadium;

The world's most technologically advanced FIFA World Cup main stadium;

The most international FIFA World Cup main stadium.

Strong project planning ability is the soul of engineering projects, and CG BUSWAY deeply agrees with this.

CG BUSWAYonce provided busway services for a circular building project at a benchmark international school. The school is an international institution that has nurtured famous biologists such as Darwin, former UK Deputy Prime Minister Michael·Heseltine, and Cambridge University astrophysicist Martin·Rees.

Prominent biologist Darwin

Former Deputy Prime Minister of the United Kingdom, Michael Heseltine

Cambridge University astrophysicist Martin Rees

The main building of the school campus is a circular structure, and the busway needs to be installed along a circular path, posing significant installation challenges. The school is located near the ocean, experiencing heavy salt spray which can corrode electrical equipment, leading to safety hazards. The school boasts a high level of modernization, featuring not only conventional teaching facilities but also a gymnasium, water sports center, design and technology center, library, and a sixth form center for university preparatory studies, making it the ultimate comprehensive facility for school-type educational facilities planning. The school authorities aim to maintain international high standards for electrical products on campus, ensuring the safety of teachers and students while meeting the complex electrical layout needs of the school.

After CG BUSWAY gained a preliminary understanding of the school project requirements, they dispatched a team of senior engineers to the school site for on-site surveys. Based on the actual situation at the site, they tailored a project installation plan for the school, ranging from project solution planning to specific preliminary design and documentation preparation work. This customized installation plan was highly recognized by the school authorities.

Firstly, CG BUSWAY configures corresponding school busway products for different application scenarios according to the situation of various places in the school, using IP65 and IP66 busways. The power supply systems for lighting and air conditioning are separately powered, with separate power supplies for lower and upper levels, ensuring that each power supply system operates independently without interference, preventing widespread power outages due to a single system failure. Each busway in different areas is equipped with plug-in interfaces for convenient branching and quick installation. The current rating of the plug-in box can be selected arbitrarily according to the load requirements, offering a much richer range of functions and options compared to conventional busways, meeting the diverse electricity needs of the school's teaching facilities.

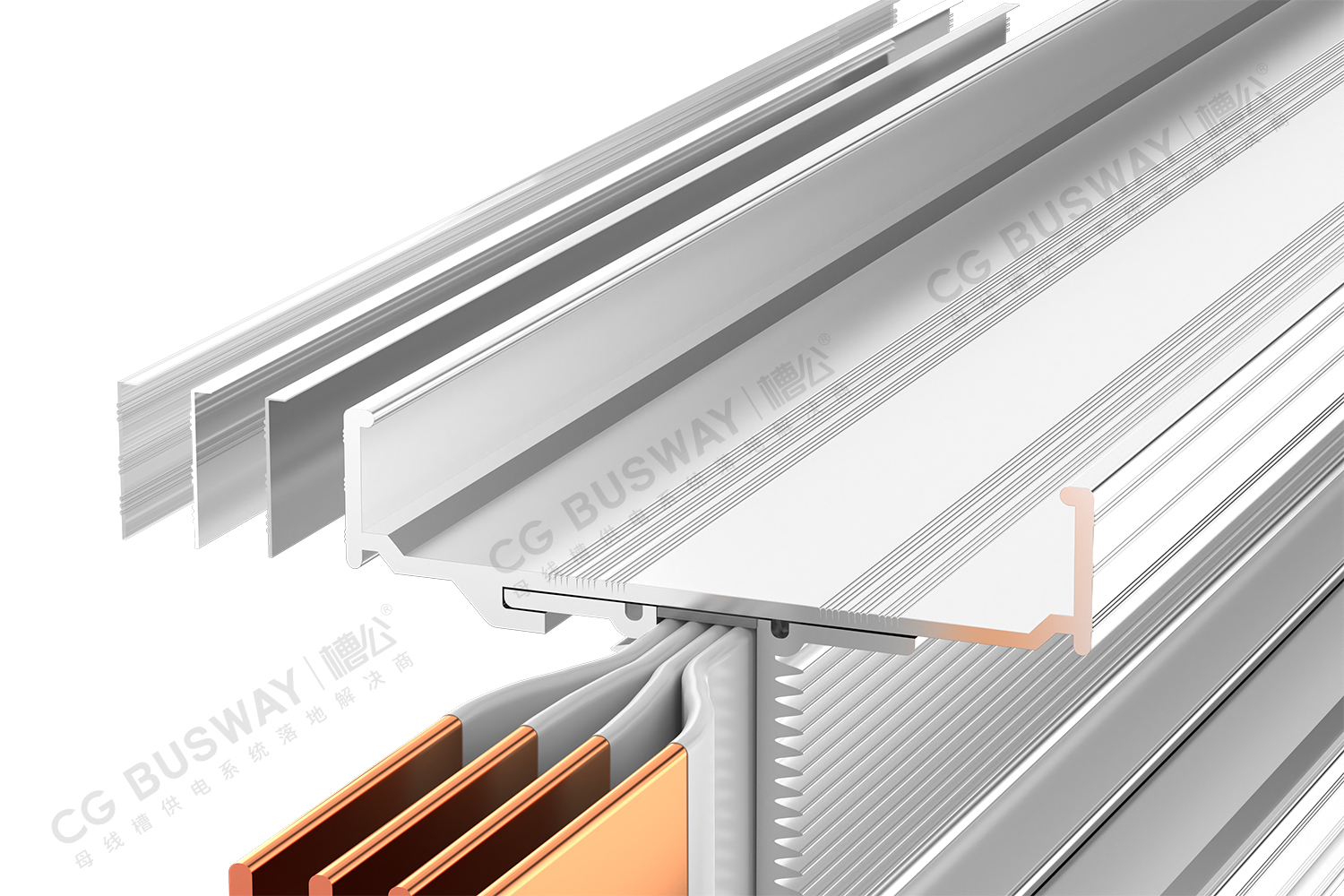

Furthermore, CG BUSWAY designed and manufactured a 118.9-degree custom bend busway for the circular main building of the school according to local conditions. Compared to regular busways, custom bend busways have higher production process requirements, needing precision down to the millimeter. Even slight differences can lead to increased product temperature rise, posing electrical safety hazards. This custom bend busway from CG BUSWAY fits perfectly on the circular main building of the school, ensuring both safety and aesthetics, and has been running smoothly for over a year now.

Compared to conventional bus ducts, CG BUSWAY bus ducts feature heat dissipation teeth with a length ≥4mm, enabling faster heat dissipation, lower temperature rise, more stable dynamic thermal resistance, and higher mechanical strength than ordinary bus ducts. The shell adopts the British Henrob riveting process, ensuring a rivet spacing ≤200mm, providing superior mechanical strength compared to the steel shell of ordinary bus ducts. The overall shell design reduces temperature rise, ensuring that schools can have uninterrupted real-time power protection 24/7 for 7 days.

The product shell of CG BUSWAY bus ducts also undergoes anodizing treatment, effectively enhancing heat resistance, wear resistance, and corrosion resistance. It has passed a 1200-hour salt spray test, efficiently resisting salt spray corrosion caused by seawater evaporation near schools.

To better serve our customers, CG BUSWAY has established the industry's first specialized team for busway systems, providing customers with a full range of services required during the operational lifecycle of busway systems, including installation, capacity expansion, reconfiguration, maintenance, and more. This initiative has earned unanimous praise from educational institutions.

All these premium services are built on a comprehensive solution planning model. Only by doing so can CG BUSWAY provide the most reasonable and feasible solutions according to customer needs and project realities, perfectly addressing customer needs and pain points, and continuously creating its own industry history.

Online

Service